VCB stands for Vacuum

Circuit Breaker, which is a type of electrical switchgear used in power systems

to control and protect electrical equipment. A vacuum circuit breaker is a kind

of circuit breaker where the arc quenching takes place in a vacuum medium. The

operation of switching on and closing of current carrying contacts and

interrelated arc interruption takes place in a vacuum chamber in the breaker

which is called a vacuum interrupter.

A vacuum that is used as the

arc quenching medium in a circuit breaker is known as a vacuum circuit breaker

because vacuum gives high insulating strength due to superior arc quenching

properties. This is suitable for most standard voltage applications because,

for higher voltage, vacuum technology was developed however not commercially

feasible.

The operation of current-carrying

contacts & related arc interruption take place within a vacuum chamber of

the breaker, which is known as a vacuum interrupter. This interrupter includes

a steel arc chamber within the center of symmetrically placed ceramic

insulators. The maintenance of vacuum pressure within a vacuum interrupter can

be done at 10– 6 bar. The vacuum circuit breaker performance mainly depends on

the material used for current-carrying contacts like Cu/Cr.

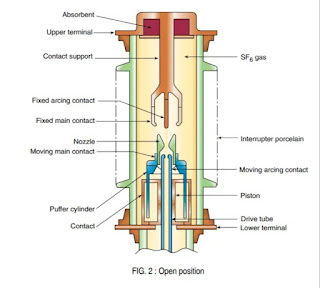

Construction of VCB:

Vacuum Chamber: The heart of

a VCB is the vacuum interrupter, which is a sealed chamber that contains

contacts and a vacuum medium. It is responsible for interrupting the electrical

current when the breaker operates. The vacuum inside the interrupter ensures

efficient arc extinction.

Contacts: A VCB consists of

two sets of contacts, namely the fixed contact and the moving contact. The

fixed contact is connected to the stationary part of the circuit breaker, while

the moving contact is connected to the moving mechanism. When the VCB operates,

the moving contact separates from the fixed contact to create an air gap, thus

interrupting the current flow.

Operating Mechanism: The

operating mechanism is responsible for opening and closing the contacts of the

VCB. It usually consists of a spring mechanism and a tripping mechanism. The

spring mechanism provides the energy to open and close the contacts, while the

tripping mechanism controls the operation of the breaker based on external

conditions such as overcurrent or fault detection.

Insulating Enclosure: The

entire VCB assembly is housed within an insulating enclosure to provide

electrical insulation and protect the components from environmental factors.

The enclosure is typically made of high-quality insulating materials such as

porcelain or composite materials.

Control Panel: A control

panel is provided to monitor and control the operation of the VCB. It includes

various indicators, switches, and relays for monitoring parameters such as

current, voltage, and fault conditions. The control panel also facilitates

manual and remote control of the circuit breaker.

Auxiliary Systems: VCBs may

incorporate additional systems for enhanced functionality and safety. These can

include features like current transformers (CTs) for accurate current

measurement, voltage transformers (VTs) for voltage sensing, and protection

relays for detecting faults and initiating breaker operations.

Working of VCB:

When a fault occurs in the

electrical system, high fault current flows through the circuit breaker

contacts, resulting in the formation of an electric arc. The VCB's primary

function is to interrupt this arc.

The VCB consists of two main

contacts, namely the fixed contact and the moving contact. When the fault

current exceeds a predetermined threshold, the trip mechanism of the circuit

breaker is activated, causing the moving contact to rapidly separate from the

fixed contact.

As the contacts separate, an

arc is initiated between them due to the ionization of the surrounding medium.

In the case of a VCB, the medium is a high-quality vacuum. The vacuum has

excellent insulating properties and high dielectric strength, allowing it to

withstand and extinguish the electric arc.

The vacuum inside the

circuit breaker creates a medium with high dielectric strength, which prevents

the arc from restricting between the separated contacts. The electric field

strength across the contacts is rapidly increased, and the electrons in the arc

are accelerated, leading to the dissipation of energy and cooling of the arc.

Due to the high dielectric

strength of the vacuum, the arc is extinguished when the current passes through

zero during the AC cycle. The rapid increase in voltage across the open

contacts helps in deionizing the medium and preventing re-ignition of the arc.

Once the arc is successfully

extinguished, the VCB allows the contacts to close again to restore the normal

flow of current in the electrical system. The reclosing operation can be done

manually or automatically, depending on the design and control mechanism of the

VCB.

Below are the protective relay which are used for VCB safety:

1) Earth Faulty Relay:

Earth fault

relay is used to detect earth leakage in power line & trip the

breaker. To detect earth leakage here CBCT is used which continuously

measures the current of phase & neutral which is zero. When earth leakage happens

then there will be difference found in phase & neutral current. This

condition is detecting CBCT & it provide the signal to earth leakage relay and

on this basis, ELR trip the breaker.

2) Master Trip Relay:

Master trip relay receives the signal from protection relays and

outputs tripping command to trip coil of a circuit breaker. Thus, it provides

isolation between the protection relays and the circuit breaker’s trip coil. If

we directly wire protection relays to the trip coil of a circuit breaker and a

fault occurs in a trip coil, then it may cause burning of protection relay

contact. The protection relays are expensive therefore direct interfacing of

the protection relay with the trip coil is not advisable. A master trip relay

is thus used for providing isolation between the protection relays and the breaker’s

trip coil.

The use of a master trip relay reduces the

complexity of wiring. If the master trip relay is not used, then we have to

wire all trip contacts of the protection relays to the circuit breaker’s trip

coil. The output of the protection relays has 110 VDC and thus the DC voltage

routes in the breaker for each protection relay. Thus, there are more chances

of DC voltage leakage. It reduces the reliability of the protection system.

Moreover, a lot of wiring cause more cost. If we use a master trip relay, we

need to carry two wires to the tripping coil.

Master relay has multiple contacts that can be

used for interlocking for tripping other breakers, annunciation, and signaling

to PLC or SCADA. A master trip relay is a high-speed auxiliary tripping relay

and it immediately issues a trip command to the circuit breaker’s trip coil.

The operating time of the relay is 10 milliseconds nominal, at rated

voltage.

We cannot directly wire the protection relays

with a circuit breaker’s trip coil that does not have anti pumping circuit. The

anti-pumping circuit interrupts the tripping command once the breaker gets

tripped. Master trip relay releases a single pulse for tripping and thus, no

anti-pumping circuit is required in a circuit breaker.

3) Supervision Relay:

As shown in the diagram,

the CB trip coil will energize when the trip relay is operated. When the CB is open, the position of the S1 &

S2 contacts are NO & NC respectively and when the CB is closed, the

position of S1 & S2 contacts are NC & NO.

DC(+Ve)

of the trip circuit supervision relay is permanently connected and through the

trip coil and S1/S2 contact, DC (-Ve) is extended to the relay. Under CB open

condition, DC (-ve) is extended through S2 contact, and under CB close

condition, DC(-ve) is extended through S1 contact.

At both the CB open

& close position, DC (-ve) is extended to the trip supervision relay and it

will not operate. Due to the failure of the trip coil or any other issue, DC

(-ve) will not be extended to the supervision relay, and under that condition,

the relay will operate.

4) Short Circuit Relay:

The working of this

circuit is based on the principle that “Current always try to flow from the

path of least resistance”. The circuit is normally open and Red LED Glows when

we connect a power source to the input terminal of this circuit. Red LED indicates

a short circuit and Green LED indicates that output power is ON. When we press

the push button coil of the relay becomes active and it switches from normally

close to normally open contact. You can see that even after leaving the push

button the relay stays in a latched condition. The current required to keep

that relay turned on is coming from a normally open terminal. This is how the

circuit comes in on state. We can connect any load to the output terminal the

circuit will work.

When overloading or short

circuit occurs or when we short the output terminals of load, a huge current

flow through the circuit. The voltage across coil terminals becomes nearly

zero, entire current tries to flow from the least resistive path. Relay

immediately Switches from normally open terminal to normally closed terminal

protecting our power supply or battery. This is how Short Circuit Protection

Using Relay works.

5) Shunt Relay:

Basically, this relay

can also be called as power relay for air circuit breaker. Shunt coil relay is

an automatically controlled relay, which can be operated remotely to open or

close a circuit breaker. Just like a PLC operates a relay, this shunt coil

relay can also be operated (on or off) by it. The operation of this relay

directly opens or closes the circuit breaker.

6) Closing Relay:

Basically, it is same as

shunt coil relay. It can also be controlled remotely via PLC, and it will

automatically open or close the circuit breaker.

.jpeg)